Arctic Technology & Icing Research Group (arcICE) is a part of institute of industrial technology of UiT. This research group focuses on developing improved scientific understanding of atmospheric ice accretion physics and technological issues realted to Arctic cold climate technology. The research group covers wide range of topics related to cold climate technology, which mainly includes:

‘To combat atmospheric icing on structures through innovative research’.

To address the structural atmospheric icing related scientific challenges and design innovative technological solutions for safe & sustainable infrastructure in the Arctic.

To conduct cutting-edge research in collaboration with the industry and academic partners with a focus on in-sight knowledge about atmospheric icing on structures, developing state of the art lab infrastructure, designing innovative technological solutions for sustainable Arctic infrastructure, increases the pool of highly trained graduates, doctoral and postdoctoral level young scientists, strengthen gender equality in STEM.

Inspired by the emerging challenges faced by the industry in cold regions, arcICE research focus on designing innovative technologies and engineering solutions to optimally combat atmospheric icing on structures in the Arctic and High North regions. arcICE aims to make transformative scientific innovations across multidisciplinary areas such as ice accretion physics, ice detection, ice mitigation and resilience/preparedness for managing ice disaster events. Such innovations can help to improve structural design, sustainability and industrial operations in cold regions. arcICE research engages postdoctoral scientists and young graduate students in the leading-edge research, helping to inform and inspire the next generation of research leaders in industry and academia. arcICE actively pursue productive collaborations with academic and industrial scientists in Norway and around the globe. Thus, committed to delivering advanced atmospheric icing and cold climate related research built on sustainable collaboration.

These research topics covers analytical, numerical and experimental analysis. The research group members has good experience and wide research network on both national and international levels. The research group has a good lab based , high performance computational resources and field observations based icing research infrastructure to carry out the advance research activities to meet the industrial demands. This includes:

arcICE research group has strong link with industry, acadmia and research organizations on national and international level and has been awarded with various national and international research grants.

arcICE research group has developed an "Icing Research Lab" that is facilitated by latest technology & modern equipment for carrying out the experiments related to atmospheric ice accretion.

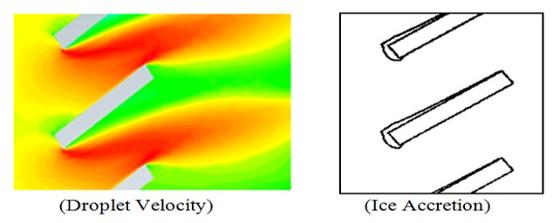

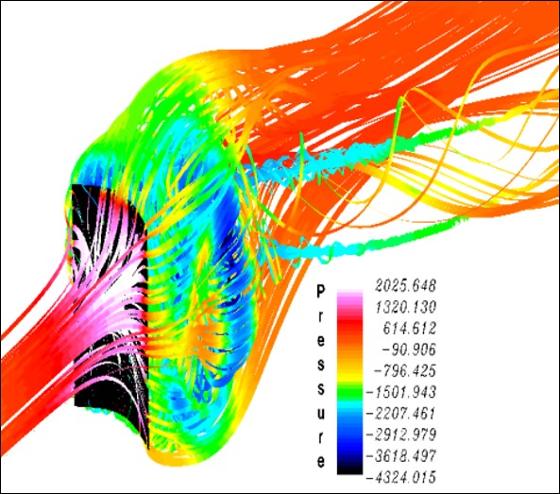

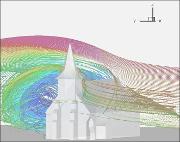

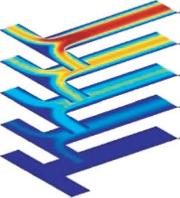

Atmospheric icing in cold regions of the world, especially in the Arctic regions, affects different sectors of everyday life, be it the construction sector or aviation, automotive or power transmission. Ice accretion limits the use of certain technologies and materials that are applicable in normal climatic zones. In order to simulate ice accretion in the laboratory and imitate the natural icing conditions, arcICE group has established research infrastructure that includes lab facilities, field monitoring station and computer aided engineering tools for advance numerical simulations.

The icing tunnel at Cold Climate Lab in UiT Narvik attributes itself with a test section dimension of 45.7cm × 47cm × 83.5cm and advanced air automizing nozzles producing droplets with MVD range of 20µm—80µm. The distinguishing feature of this icing tunnel is its easy portability for outdoor testing of different models. The maximum achievable wind speed is 10ms-1. The temperature control unit supported with HMI can maintain temperature at any value between -20.0℃ to +30.0℃. Other salient features are as follows:

|

|

|

|

|

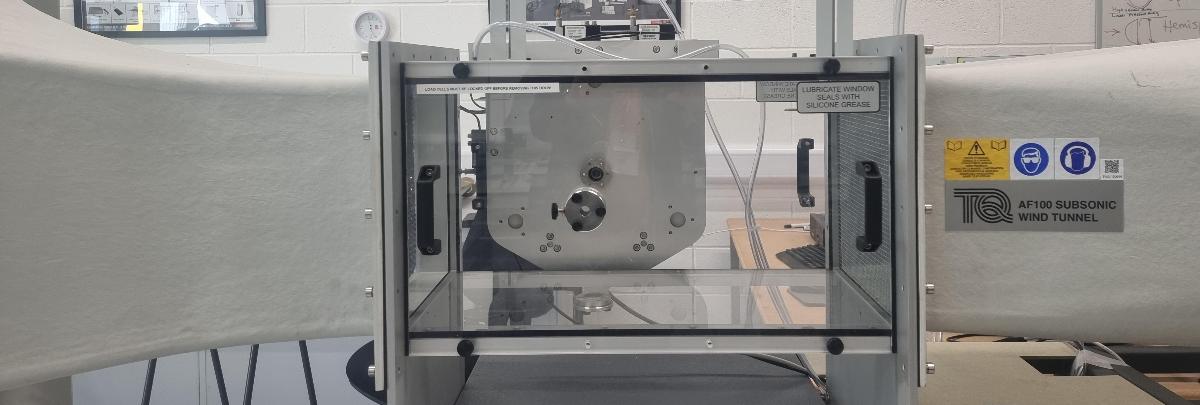

arcICE research group has an open loop wind tunnel supported by a 3-axis balance system to measure lift, drag & pitch of model under observation. This balance system is also interfaced with Data Acquisition System (DAQ System) to directly record pressure readings & aerodynamic forces. Other specifications are as follows:

|

|

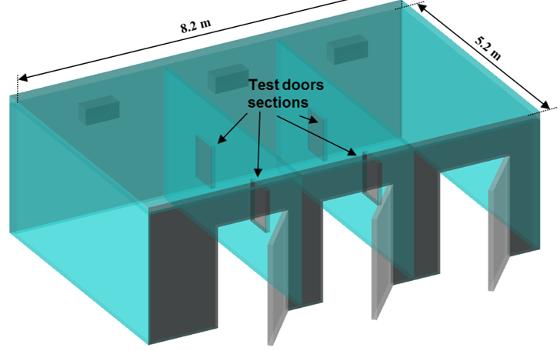

Cold climate chamber comprises of 3 separate rooms equipped with chillers and frequency controlled ice generators. Cooling system is able to regulate temperature between -20.0℃ to +30.0℃ and is made functional by Human Machine Interface (HMI). All the rooms implement programmable thermocouples, weather sensors etc. CCTV camera and thermal infrared camera are available for live video monitoring. An advanced DAQ system is able to record data from multiple sensors during experimentation.

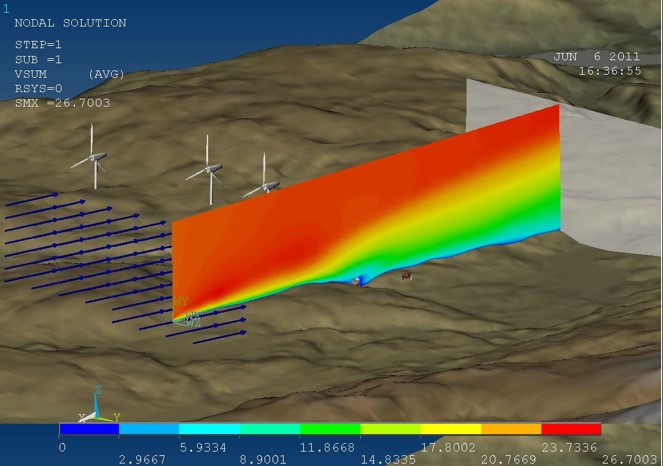

Cold climate lab is used extensively for aerodynamic testing and is thus facilitated with advanced and latest softwares used worldwide for R&D purposes. The available state-of-the-art Computer Aided Engineering (CAE) numerical solvers include:

|

|

|

|

|

|

|

|

|

|

An ice monitoring station is installed by Icing Research Group near Linken tower at Narvikfjellet (located at 1006 m.a.s.l). The objective is to collect longterm metreological dataset for educational & research purposes in order to study ice accretion phhysics and resultant ice loads on structures.

This field ice monitoring station consists of various advance icing sensors, meteorological sensor and dual lens heated web camera that can help us to closely study the ice accretion physics and resultant ice load on structures. Web camera is available for 24-hours monitoring using 4G connection. This field station consists of following sensors.

|

|

Spray bar system at UiT is a portable, horizontal array spraying mechanism that can be used both indoor & outdoor for icing experiments. It can simultaneously house 6 air automizing sparying nozzles that can produce droplets with MVD 20µm—80µm. Applications of spray-bar system include: ice accretion studies on small or medium size scaled models, effect of air-water proportional variation for ice formation, deicing system development etc.

|

Several experiments have been conducted by research group at UiT using this spray bar system to study icing on airfoil/bridge models and general purpose drones to study ice impact on them.

|

|

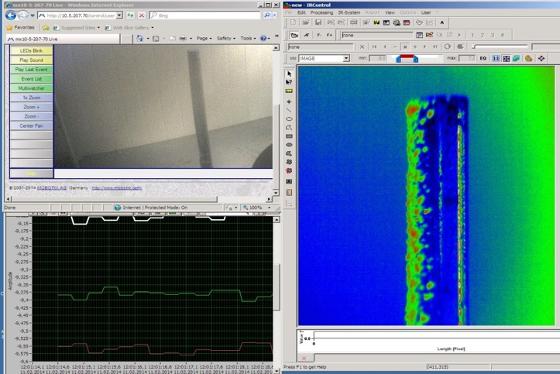

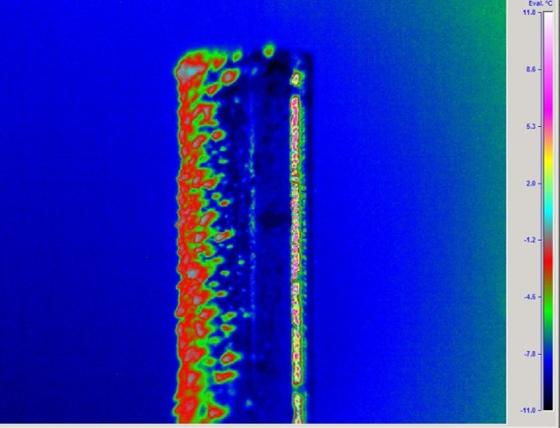

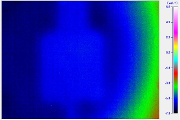

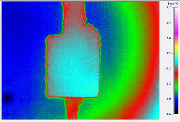

Icing Research Group is utilizing its capabilities in devising techniques to identify different icing types based on emissivity and thermal detection. For this purpose FLIR A615 camera modified to sustain subzero icing conditions is being used along with IR Control software utility. The future studies in this arena may lead to reverse engineering i.e.: designing an anti-icing/deicing system after identifying a specific ice type using thermal IR.

|

|

|

|

|

|

|

|

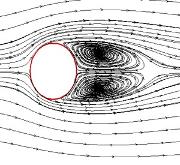

arcICE group has an advance PIV system, connected with aerodynamic subsonic wind tunnel. The system can be used to study the complex flow behavior for various applications.

.png)

Hamza Asif, Muhammad S Virk, Jan-Arne Pettersen, Pourya Pourhejazy, ‘ A review of ice accretion, detection and mitigation methods for the gondola infrastructure application, (2026), Cold regions science and technology. DOI: https://doi.org/10.1016/j.coldregions.2026.104847

Manaf Muhammed, Anvesh Dhulipalla, Harsha Sista, Hassan A. Khawaja, Muhammad S. Virk, Hui Hu, ‘An experimental investigation of transient ice accretion process on a high-lift airfoil model for UAV applications’ (2026). Experimental Thermal and Fluid Science.