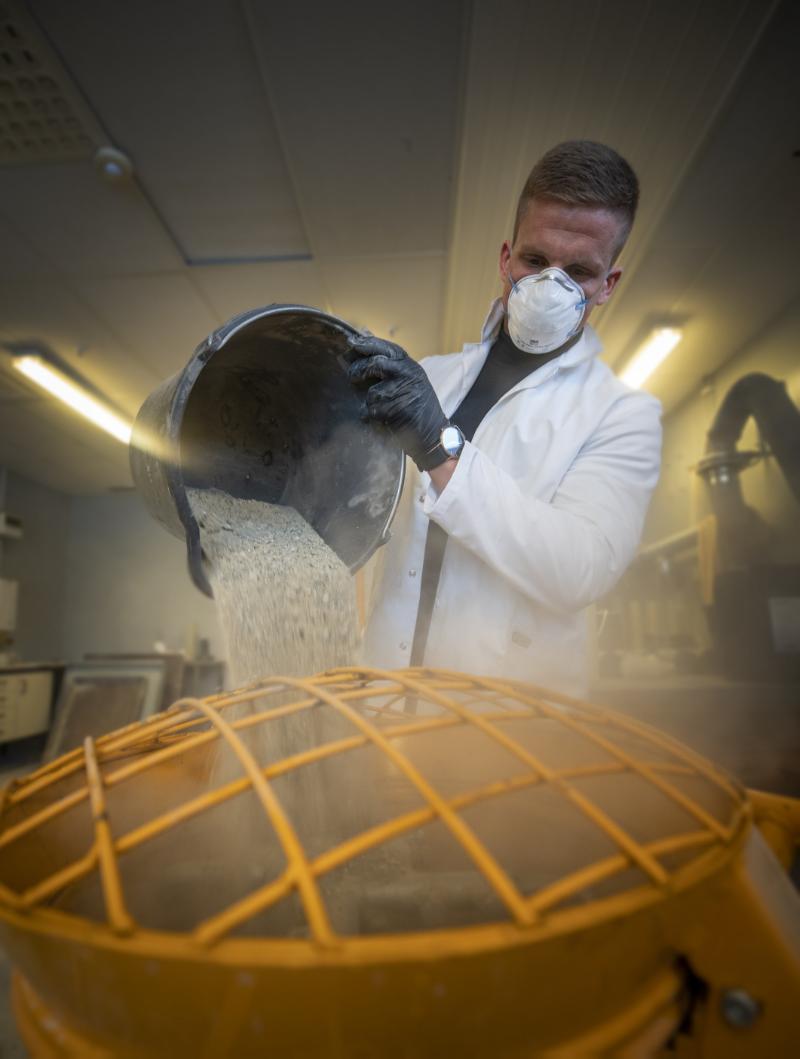

The concrete and aggregates laboratory has equipment for testing everything from clay to rock, both for building on and for testing whether the masses can be used as aggregates in concrete, asphalt, road, dam and railway construction. We also perform all types of tests on fresh and hardened concrete as well as grout and shotcrete. Our students have lab exercises where they carry out most of our tests and we assist in connection with assignments and research.

For testing loose materials and rock masses

- Sieve equipment for grain distribution and slurry analysis

- Equipment for testing density, water content, absorption, humus content and compaction

- Crusher for rock

- Los Angeles machine for mechanical testing of crushed rock. Both normal and railway ballast

- Ball mill machine for studded tire wear test crushed rock

- Micro Deval machine for wear, degradation of crushed rock. Both normal and railway ballast

- Equipment for determining chipping and grain shape index. Both normal and railway ballast

- We are also helpful with work around CE marking of products

- Petrographic

For testing fresh and hardened concrete

- Pressure press for testing compressive strength and slit tensile strength

- Pressure press for fiber-reinforced shotcrete

- Grinding machine for surface grinding of cores

- Carbonation test

- Water absorption

- Permeability

- 2 mixing machines

- Equipment for testing fresh concrete regarding air content, expansion, sink, temp etc.

- Various microscopes, scales, etc. all calibrated and certified

- Good facilities for testing and separate test stations between research, external assignments and student exercises

We also have certified equipment and operators for thermography, density testing, land surveying, sound testing, water testing with regard to ions, chlorides and more.

The laboratory is certified through the Norwegian Testing Council certificate no. 273 to carry out all our tests and as an impartial third party.

Testing area AI, AII, B1, FI, FIII and PI

Laboratory manager Boy-Arne Buyle's personal certified competence through the Concrete Training Council is part of the laboratory's documented competence according to the requirements of the current NS-EN standards.

The manager is approved by the Concrete Training Council on the basis of documented prior knowledge, practice and additional courses with passed exams in the classes:

UMKL assembly and inspection manager - extended control

UPKU production and inspection manager - extended control and

TKL Aggregate inspector - laboratory assistant.

SLBU Shotcrete and inspection manager, utf.kl 3

We have good contact with business and public authorities and our talented students directly benefit from the work we do in the lab through teaching, inspections and the like.

We act as a link between the industry, academia and research and actively participate as a leader in the competence group of the Arenaklyngen CIC (Concrete Cluster).

We conduct courses in collaboration with NESO and EBA.

Our main focus in research is the recycling of concrete into new concrete and other products, renovating concrete with new methods and developing and testing new concrete recipes that use recycled concrete, touf and composite reinforcement.

We also participate through PIANC (the International Port Association) see pianc.org in MarCom WG 162 – Recommendations for increased durability and service life of marine concrete infrastructure and will this year help start a new working group that will develop an image-based checklist system for builders.

Contact information

Boy-Arne Buyle, Senior Engineer

Tel.: 769 66 203 / 99 10 61 86

Epost: boy-arne.buyle-persson@uit.no

Preben Aalmen

Tel.: 97 95 21 88

Epost: preben.aalmen@uit.no

Postal adress:

Lodve Langes gate 2

Postboks 385

8505 Narvik

Page editor: Persson-Buyle, Boy-Arne

Documents

| Concrete_Laboratory_Equipments |