Ar2CorD Project Launches Long-Term Low Carbon Concrete Test Facility in Narvik Harbour!

The research team from the Arctic University of Norway, under the supervision of Iveta Nováková, achieved their project goal.

The Ar2CorD Project – Low Carbon Concrete for Arctic Climate with Excellent Sustainability and Durability – has successfully established a pioneering long-term durability test facility for low carbon concrete (LCC) in Narvik Harbour, Norway. The project, co-funded by Interreg NPA, a collaboration between universities and industries across Norway, Sweden, Finland, Iceland and Greenland, started in January 2023 and aims to optimise LCC using supplementary cementitious materials (SCMs) and evaluate its performance under harsh Arctic conditions. Project leader Iveta Nováková, PhD candidate Rekik D. Derso, laboratory leader Boy-Arne Persson-Buyle and IVY volunteer Hanife Ekinci are the main research team members from The Arctic University of Norway involved in station establishment.

Innovating Concrete for Arctic Conditions

Achieving a balance between durability and sustainability is a critical challenge for new concrete structures in Arctic climates, where extreme temperature fluctuations and marine exposure significantly accelerate material degradation. The Ar2CorD project aims to evaluate the long-term durability of LCC through a combination of accelerated laboratory testing and field monitoring. Narvik Harbour, an ice-free port during winter, was chosen as the optimal location for this innovative facility.

|

Narvik Harbour: area before installation |

Designing the Monitoring Station The monitoring station design followed the RILEM TC 289-DCM guidelines on long-term marine exposure sites. The establishment process was divided into four stages: selecting the location, designing holders and samples, setting up monitoring and testing systems, and preparing the test concrete. The primary focus of the station is to evaluate freeze-thaw resistance, one of the most critical durability challenges in Arctic coastal areas. |

Concrete samples were cast at the UiT Betong Lab in Narvik in August 2025. Five distinct concrete mixes were prepared, including: a reference mix made exclusively with Portland cement, two mixes with partial replacement of cement by Icelandic volcanic pozzolan combined with limestone filler, one mix containing granulated blast furnace slag, and one mix with 100% replacement of coarse natural aggregates by recycled concrete aggregates.

| Each mix design consisted of four samples with dimension of 200 × 600 × 900 mm, resulting in a total of 20 concrete samples. |

Casting of concrete samples in the laboratory, UiT Narvik |

Strategic Placement and Construction

The individual concrete samples are exposed to three distinct marine zones: one sample in the atmospheric zone, two in the splash/tidal zone, and one in the submerged zone. This setup was chosen because of the broad tidal zone, up to 465 cm.

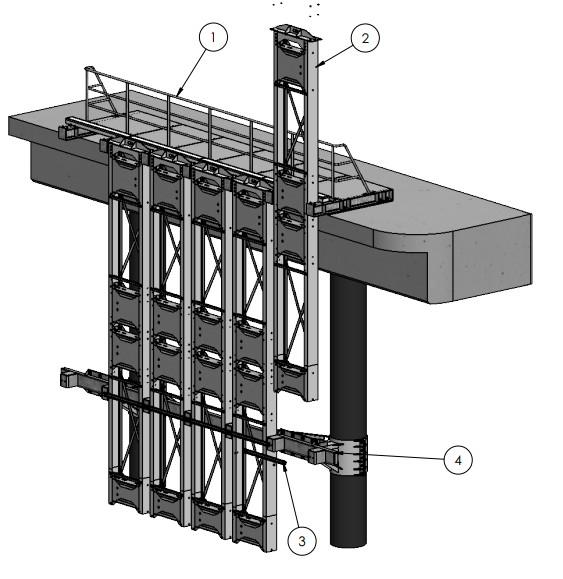

The construction of the station was completed in December 2025. The station system, featuring five sliding steel subframes, was designed by Kjell Mikalsen of 2K Tech AS, with production and assembly carried out by Ofoten Mek AS. A team from UiT participated in the frame assembly and conducted initial tests on the concrete samples before their exposure.

|

Technical design of the station by 2K Tech AS |

Assembly of the subframe at Ofoten Mek AS |

Advanced Monitoring for Long-Term Insights

Freeze-thaw effects will be monitored directly via periodic ultrasonic measurements and surface 3D scanning and indirectly by temperature and chloride content in different depths measured by inbuild mulitsensors from DuraMon. For precise durability assessment, DuraMon, a Swiss company specializing in concrete monitoring, installed embedded multisensors in the samples. These sensors enable continuous, real-time monitoring of:

- Temperature

- Chloride concentration

- Concrete electrical resistance (moisture)

- Corrosion current

- pH

- Steel electrical potential

Additionally, the project incorporates destructive testing through periodic core drilling to measure chloride migration, compressive strength, and carbonation depth. This combination of non-destructive and destructive testing ensures the reliability of sensor data and provides a comprehensive understanding of concrete behavior over time.

The DuraMon sensor system integrates all critical parameters in a compact module with a robust data logger. Its flexible, wireless monitoring platform allows for customizable plans, ensuring that the station’s data aligns with project-specific requirements.

|

Dr. Emanuele Rossi from Duramon is placing the data loggers on the steel frames |

3D scanning of concrete surfaces by Hinnstein |

|

Placement of subframes in the fix station holders |

Transport of subframes to the station |

A Step Forward for Sustainable Arctic Construction

By establishing this long-term durability test facility, the Ar2CorD Project is setting up a new benchmark for sustainable, low carbon concrete in Arctic marine environments. The insights gained from this station will guide the development of resilient, eco-friendly concrete solutions capable of withstanding extreme climates, benefiting both research and the construction industry.

|

Opening of the long-term monitoring station at Narvik Harbour: Hanife Ekinci, UiT; Iveta Nováková, UiT; Rekik D. Derso, UiT; Kenth Ivar Ljunggren Kvitvik, Narvik Harbour; Børge Edvardsen Klingan, Narvik Harbour; Bård Arntsen, Sintef; Raymond Riise, UiT; Preben Aalmen, UiT; Boy-Arne Persson-Buyle, UiT; Roger Nicolaisen, Ofoten Mek AS (from left) |

Finally, I would like to thank all involved persons and companies, namely Narvik Harbour for providing the exposure side and support during entire process from planning to building the station; HGB , the local concrete producer for supplying us with aggregates for sample production; Mapei, the industry chemistry producer for donating concrete admixtures; Swecem, cement and concrete input material producer from Sweden to secure ground granulated blast furnace slag; Solorbioenergi, producer of renewable energy based on wood fuel who provided their wase strem wood waste ash; Elkem, the chemical company that provided microsilica for concrete preparation and Nordland Betong, concrete producer from Bodo who supplied us with recycled concrete aggregates. Furthermore, to the Ar2CorD project partners for discussion and material supply, Heidelberg Materials Sement Norge and UiT for allowing me to build such a unique test facility.

.jpeg)